Learn all about Preventive Maintenance in a simple way!

Preventive Maintenance. This is an increasingly sought-after solution by organizations looking to perform at the highest cost. This is because it aims to prevent equipment failures, so that the operation is continuous and it is not necessary to bear repairs and emergency changes.

Today, more than necessary, anticipating problems and keeping the company with high performance has become a fundamental issue, since the market expects agility, competition is high, customers are demanding and expenses must be controlled to minimize losses.

If you’ve come this far, it’s probably because you’re interested in getting this and other differentials brought by proactive conduct. In that case, you’ve come to the right place. Follow our article and learn all about it!

Learn more about Preventive Maintenance

According to NBR 5462,of the Brazilian Association of Technical Standards (ABNT), preventive maintenance is the set of technical and administrative actions with the objective of reducing the probability of failure or degradation of the operation of an item.

In practice, the processes take place through the planning of periodic inspections on various types of machinery and equipment,whether industrial, automotive, hydraulic, among others. Some results, in this case, are the conservation of assets, the safety of workers, customer satisfaction and the economy.

The issue of maintenance in times of Industry 4.0

Preventive maintenance is a concept that began in the 1950s, between the Period of World War II and post-war, when the sector realized the need to ensure reliability and availability of assets while maintaining productivity. Since then it has been used to restore the original conditions of the equipment, before potential failures arise.

Like countless other processes, this has undergone significant changes from industry 4.0 technologies. Today, what is expected is to perform an increasing number of maintenance activities, with increasingly optimized features.

For this, technological resources such as artificial intelligence and internet of things (IoT) are used, which help in the insertion of the future element, enabling us to have answers to situations that have not yet occurred, but would if no action were taken.

One of the concepts of Industry 4.0 is the creation of a virtual model of the machines and the entire production system, so that it is controlled and can be operated remotely. This is facilitated with the use of sensors, which send the control software the situation of each equipment. The system, which allows the detection of irregularities in real time, can be based on preventive maintenance, corrective maintenance and predictive maintenance.

Corrective maintenance x preventive maintenance x predictive maintenance: understand the differences

As we mention, industrial maintenance is composed of three methods, which are applied at different times, as well as bring different results. To make you understand each of them better, here’s what they’re all about:

- Preventive maintenance: aims to reduce failures or falls in machine performance through a pre-elaborated schedule in which periodic inspections are included;

- Predictive maintenance: actsin the routine inspection of equipment to identify abnormalities that may cause problems. This periodic monitoring is used by data collected through monitoring or inspections. The most used techniques are vibration analysis, ultrasound, visual inspection and non-destructive analysis techniques.

- Corrective maintenance: Occurs when a fault is already detected and activities occur in an unscheduled manner. As can be imagined, in this case there may be interruption in activities and unexpected costs due to the actions carried out in an emergency manner.

From what you have been able to prove, you need to have an adequate maintenance planning, which includes preventive maintenance, to avoid losses, to the same extent that you get better results.

The importance of preventive maintenance for your organization

It is possible that you have already heard the saying “the cheap that comes out expensive”. It applies well when it comes to lack of maintenance in an organization. After all, when inspections are seen as a cost and not an investment, the company ends up spending exorbitant amounts with unexpected failures.

In addition, equipment that is not reviewed periodically may have loss in performance without demonstrating, requiring a higher expenditure of electricity, for example.

When the organization invests in preventive maintenance, the scenario is just the opposite. In this case, some advantages are:

- ensures maximum use of the life of the machines;

- optimizes resources for reasons such as having more time to search suppliers, lower costs of repairs and parts changes, and minimizing overtime by unexpected stops;

- quality of the operation, since production is carried out on time and, consequently, customers are satisfied;

- prevention of accidents at work, ranging from the simplest to the most serious, capable of bringing incalculable damage.

With these factors, it is clear the importance of this type of maintenance to decrease the probability of failures. But in order to be advantageous and make sense for the company, it needs to beused strategically, based on well-structured planning and the best partnerships and tools.

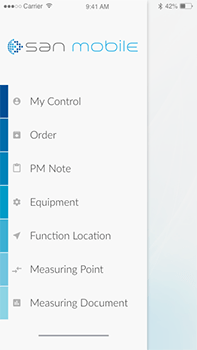

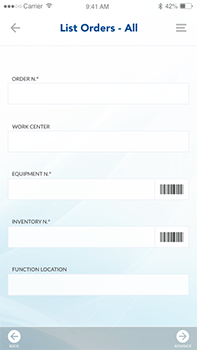

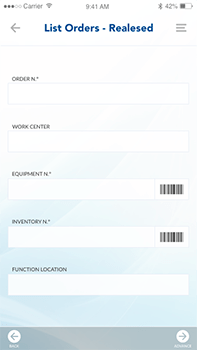

To help companies perform preventive maintenance and their other subtypes efficiently, Nalbatech provides SAN Mobile, a platform that helps teams perform consultations, updates, data release and order confirmation in real time, 100% compatible with SAP® PM module.

This brings process automation securely and simply, all in user-friendly, fast and intuitive interfaces, so companies minimize errors and reduce time spent on highly transactional processes.

We hope that our article will help your organization to rely on well-structured maintenance processes. Interested in knowing Nalbatech’s solutions for process automation? So contact one of our expertsright now!