Industry 4.0 – What changes in maintenance?

Technology is in advance and every day the concept of industry 4.0 gains more strength in all areas of the market. The first three industrial revolutions allowed mass production, assembly lines, electricity and information technology. The fourth generates a much deeper impact, as it is characterized by a set of technologies that makes the fusion of the physical, digital and biological world. But what is the impact of industry 4.0 on maintenance? Check out the following article.

Industry 4.0: what is it?

It was at the Hanover Fair in 2011 that the term Industry 4.0 was first used. At the time, it was a way of naming the changes that occurred in industrial processes through technology and computerization. In fact, it is an industry concept that encompasses the main technological innovations in the areas of automation, control and technology applied to manufacturing processes.

In summary, Industry 4.0 means the increase of technologies in the manufacturing industry, with machines and equipment fully integrated into internet networks. With this, the management of processes becomes simpler and in real time, allowing access from any location.

However, according to information from the Brazilian Agency for Industrial Development (ABDI),about 43 of the companies still do not identify digital technologies as driving factors in the industry. This is because the high cost of implementation, the difficulty of return on investment, the structure and the new culture end up generating great challenges for the adoption of these technologies in manufacturing.

Industry principles 4.0

Industry 4.0 has features that allow you to collect and analyze machine data. With this, the processes become more agile and efficient, improving production and consequently reducing costs. However, for its implementation it is necessary to know and apply the six principles of industry 4.0 that determine intelligent production systems. Check out!

1. Interoperability

Interoperability addresses the ability of systems to connect with other systems. In summary, the contact between the employees responsible for productivity and the equipment used in the process becomes possible through the Internet of Things and a management system, such as ERP, for example. With this, you can collect data that can be used by a company value chain.

2. Modularity

With Industry 4.0 it is possible to plan manufacturing in modules, that is, with a production more focused on customization. In summary, manufacturing can be done according to the demand, coupling and uncoupling of modules in production. This brings much more flexibility to modify equipment demands very easily. With this, it is also possible to save more and improve production.

3. Decentralization

This is one of the principles of the fourth most anticipated revolution by the market, as it will be able to reduce errors and costs. Moreover, the technologies involved in the production processes of a company already adapted to Industry 4.0, allow systems to have autonomy to make decisions according to the needs of manufacturing. In this process, electronic tools know exactly what to do through machine learning-based analytics.

4. Service Guidance

This principle refers to the connection of humans and machines to perform certain tasks. This concept also aims to make the applications used available as a kind of service. The advantage is to standardize methods and processes, so that practices are followed more easily and criteria, according to planning.

5. Real-time capability

This principle is fundamental because it is about the ability to react to the events of the value chain in real time. The sum of data usage and a management system, that is, using the Internet of Things in favor of your company allows you to control and analyze in real time everything that is necessary for decision making. In addition, it makes known all the steps and development of each process.

6. Virtualization

Virtualization is a principle that allows information to be compiled. For this, it is necessary to have a team trained in dataanalysis, so that the information collected is a differential for manufacturing, also generating competitiveness in the market.

Industry 4.0 in maintenance: understand the relationship

With the arrival of Industry 4.0 in maintenance, processes have evolved. That is, the term preventive became predictive, after all, the new technologies allow to identify sources of potential failures in order to take action before they occur.

The changes that the fourth industrial revolution brought have a direct impact on the processes and the way products are manufactured. The impact of Industry 4.0 on asset maintenance is made through solutions, which enable management in production systems to become simpler. Thus, you can have a greater capacity for operation and planning.

This makes it easier to identify the causes of errors and avoid them before they even occur. Industry 4.0 in maintenance is premised to analyze performance indicators and predict the causes of equipment failures and depreciation. In this process, risk analysis techniques are widely used.

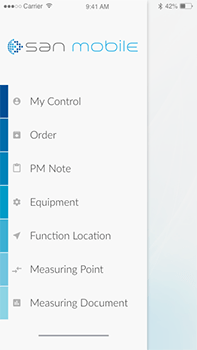

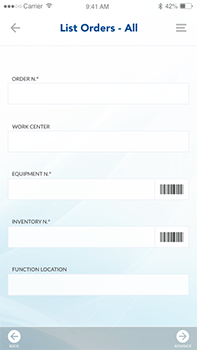

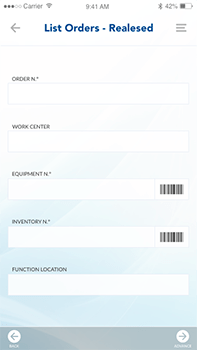

Affordable data from anywhere

The dynamics of maintenance in the fourth revolution is totally new and unites the concepts of preventive and predictive maintenance with intelligent monitoring. This is all integrated with online and real-time access to information in the production chain. Thus, the professional can access the data of any factory, regardless of where it is located, and can even be in units of different countries, for example.

This information can be important for quick and assertive decision making. Thus, it is possible that the maintenance area has an increasingly strategy applied to the processes, increasing productivity in the organization and reducing losses by stopped machines.

For example, if there is an imminent failure in the components of a machine, the professional can verify exactly which equipment is in trouble and the exact position of the occurrence. It is also possible to generate graphs through an integrated software, facilitating the study of the source of the failure and the behavior of the problem. Industry 4.0 in maintenance also allows systems to be interconnected providing greater control of processes.

Industry 4.0’s maintenance solutions

We have already realized how much Industry 4.0 impacts predictive maintenance. In fact, the industry needs to be highly effective in its processes to meet the numerous demands, that is, they need to meet strict supply schedules. Any failure can interfere with the production chain.

In this sense, technologies bring new features to improve predictive maintenance and make it more efficient, cost-effective, and more accurate. But for this, it is necessary to use different technological solutions, which allow to provide data for operational and informative support. These data are highly essential for the performance of managers and maintenance teams.

Machine Learning

Industry 4.0 in maintenance works with Machine Learning linked to artificial intelligence and brings an elementary concept to the modern industry. Applying this reality to equipment is much simpler today.

The technology and automation features allow this implementation more conveniently for professionals. With Machine Learning it is possible to program and manage large industries, organizing the demands and routines of maintenance professionals.

Big Data

We’ve talked about how important data is and how it can be used through Industry 4.0 in maintenance. In this era, they are highly important items, as they allow to control methodologies and management systems in a strategic way. Thus, Big Data becomes indispensable in predictive maintenance.

Through Big Data, information collected in relation to failures, maintenance and repairs becomes an important tool to provide an overview of equipment performance. In addition, with this data in hand it is possible to replace any equipment easily and even have a quick and accurate decision making if necessary.

IOT (Internet of Things)

The Internet of Things is increasingly present in industrial production processes and is a great ally of predictive maintenance. After all, the productive sector has been transformed with the implementation of new technologies, with sensors and data sharing. With IOT, three technology fronts are generally applied in the industry, such as sensor-driven computing, industrial analysis, and intelligent machine application.

Data that was once inaccessible, become part of the day-to-day industrial planning. With this, it is possible to create new sources of revenue and explore the capabilities of the fronts implemented with Industry 4.0 in maintenance. In addition, any failure is quickly identified and reported to the responsible teams, allowing for early action.

And you, like to know more about how Industry 4.0 is positively impacting maintenance? Also know that Nalbetech can take your company to a high level in this direction, bringing the best technological solutions. Want to know more about it? Please contact us.